Water wells play a vital role in providing clean and accessible water to various communities and households. Understanding how water wells are drilled is key to maintaining their functionality and ensuring a consistent water supply. In this article, we will delve into the basics of well drilling, the preliminary steps involved, the drilling process itself, post-drilling procedures, and the maintenance of water wells.

Understanding the Basics of Well Drilling

The Importance of Water Wells

Water wells are essential for accessing groundwater, a valuable natural resource that serves as a primary source of drinking water in many areas. Unlike surface water sources, such as rivers and lakes, groundwater is protected from contamination and is often of superior quality.

Water wells provide independence from municipal water supplies, particularly in rural and remote locations where piped water infrastructure may not be available. Additionally, during times of drought or emergencies, well owners can rely on their wells to sustain their water needs.

But have you ever wondered how these wells are constructed? Let’s dive deeper into the world of well drilling and explore the different types of water wells available.

Different Types of Water Wells

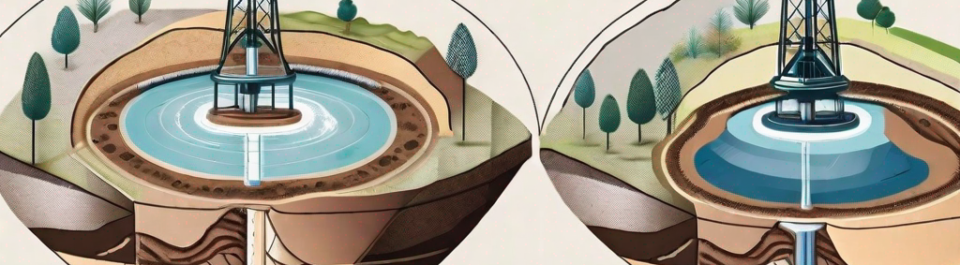

There are various types of water wells, each designed for specific purposes. The most common types include dug wells, driven wells, and drilled wells. Dug wells are shallow excavations that collect water from permeable soil or rock layers. These wells are often found in areas with high water tables, where the groundwater is close to the surface.

Driven wells, on the other hand, are constructed by driving a pipe or casing into the ground until it reaches water-bearing formations. These wells are typically used in areas with sandy or gravelly soils, where water can easily flow into the well.

However, this article will focus primarily on drilled wells, which are deeper and have the potential to tap into deeper aquifers, providing a more reliable and plentiful water source.

Drilled wells are created by using a drilling rig, which is a machine specifically designed for drilling holes in the ground. The rig is equipped with a drill bit that rotates and cuts through the soil and rock layers. As the drilling progresses, sections of steel casing are inserted into the hole to prevent it from collapsing.

Drilled wells can reach depths of several hundred feet or more, depending on the water table and the specific geology of the area. These wells are often equipped with pumps to bring the water to the surface, where it can be stored and distributed to the intended users.

One advantage of drilled wells is that they can tap into deeper aquifers, which are underground layers of permeable rock or sediment that contain water. These aquifers can hold vast amounts of water and provide a more reliable source of water, even during dry periods.

Another benefit of drilled wells is that they can be customized to meet specific water needs. For example, if the water in a certain area contains high levels of minerals or contaminants, a drilled well can be designed with additional filtration systems to ensure the water is safe for consumption.

Overall, drilled wells are a popular choice for homeowners, farmers, and businesses alike, as they offer a reliable and sustainable source of water. However, it’s important to note that the drilling process requires expertise and should be carried out by licensed professionals to ensure the well is constructed safely and efficiently.

Now that you have a better understanding of the different types of water wells and the benefits of drilled wells, you can appreciate the importance of well drilling in accessing clean and reliable water sources.

The Preliminary Steps Before Drilling

Site Selection for Well Drilling

Selecting an appropriate site for drilling is crucial to ensure a successful well. Various factors need to be considered, such as geological surveys to determine the presence of groundwater, accessibility for drilling equipment, and compatibility with property boundaries and building codes.

Geological surveys involve conducting extensive research and analysis of the land to identify potential sources of groundwater. This process includes studying the topography, soil composition, and rock formations in the area. By understanding the geological characteristics, drillers can pinpoint the most promising locations for drilling.

Accessibility is another important factor to consider. Drilling equipment is heavy and requires sufficient space for maneuverability. The site should have adequate access roads and clear pathways to accommodate the transportation and operation of drilling machinery.

Furthermore, property boundaries and building codes must be taken into account. It is crucial to ensure that the chosen site is within the legal boundaries of the property and complies with local building regulations. This helps prevent any legal complications or disputes that may arise during or after the drilling process.

Consulting with a licensed well driller or hydrogeologist can provide essential insights into site suitability and help avoid potential complications down the line. These professionals have the expertise and experience to assess the geological conditions, evaluate the accessibility of the site, and ensure compliance with legal requirements.

Legal and Environmental Considerations

Prior to drilling a well, it is essential to familiarize oneself with local regulations and permits. These requirements vary from region to region and may involve obtaining permits from relevant authorities and adhering to environmental protection guidelines.

Local regulations often dictate the necessary permits and approvals needed for drilling a well. These permits ensure that the drilling process meets safety standards and environmental regulations. They may require the submission of detailed plans and specifications, as well as the payment of fees.

In addition to legal considerations, environmental factors must also be taken into account. The proximity of the well to potential sources of contamination, such as industrial sites or agricultural activities, should be carefully evaluated. This assessment helps prevent the risk of groundwater pollution and ensures the long-term viability of the well.

Proper safeguards should be in place to protect the groundwater quality. This may involve implementing measures such as installing protective casings, monitoring systems, and regular testing to detect any changes in water quality. Adhering to environmental protection guidelines and best practices is crucial to minimize the impact on the surrounding ecosystem and maintain the sustainability of the groundwater resources.

By considering both legal and environmental aspects, well drillers can ensure that the drilling process is conducted responsibly and in compliance with regulations. This not only protects the environment but also safeguards the health and safety of the community relying on the well for their water supply.

The Drilling Process Explained

When it comes to accessing the water-bearing formations below the earth’s surface, well drilling is the go-to method. This process involves the use of specialized equipment that is specifically designed to penetrate the ground and reach the desired depth. Let’s take a closer look at the equipment used in well drilling.

Equipment Used in Well Drilling

The primary equipment used in well drilling includes a drilling rig, drill bits, drilling fluids, pumps, and casings. These components work together to ensure a successful drilling operation.

The drilling rig is the heart of the operation. It is a large machine that provides the necessary power and stability to drill into the ground. The drill bits, which are attached to the drilling rig, come in various designs to suit different types of ground. These bits rotate and penetrate the ground, creating boreholes of varying diameters.

Drilling fluids play a crucial role in the drilling process. They are often a mixture of water and additives that serve multiple purposes. One of their main functions is to reduce friction between the drill bit and the ground, allowing for smoother drilling. Additionally, drilling fluids help to cool the drill bit and carry the excavated material, known as cuttings, to the surface.

Now that we have a better understanding of the equipment used in well drilling, let’s delve into the phases of the drilling process.

Phases of the Drilling Process

The drilling process can be divided into several phases, each serving a specific purpose to ensure a successful well. Let’s explore these phases in more detail.

The initial phase of the drilling process involves excavating the borehole to the desired depth. This is where the drilling rig and drill bits come into action. As the drill bits rotate and penetrate the ground, boreholes of varying diameters are created. It is during this phase that casing pipes are inserted into the borehole to maintain stability and prevent the collapse of surrounding formations.

Once the desired depth is reached, the next phase begins – well development. This phase focuses on removing any drilling debris and enhancing the flow of water. Various techniques can be employed during well development, such as surge block, air-lifting, or high-pressure jetting. These techniques help to clear the borehole and improve the overall performance of the well.

Finally, the last phase of the drilling process is the completion of the well. This involves installing a well cap or seal, which serves multiple purposes. Firstly, it acts as a safeguard, preventing surface water contamination from entering the well. Secondly, it secures the wellhead, ensuring the well remains intact and protected.

So, there you have it – a comprehensive explanation of the drilling process, from the equipment used to the various phases involved. Well drilling is a complex and fascinating process that allows us to access the valuable resource beneath our feet – water.

Post-Drilling Procedures

After drilling, well development procedures are crucial to optimize the well’s performance. Development techniques, such as surging or pumping out sediment, help clear the borehole and improve water flow. This process ensures that the well is properly connected to the aquifer and maximizes its yield.

During the well development process, it is important to consider the geological characteristics of the area. For example, if the well is drilled in an area with high sediment content, additional surging may be required to remove the excess sediment and prevent clogging. On the other hand, if the well is located in a rocky formation, specialized tools may be needed to break through the hard rock and enhance water flow.

Once the well is adequately developed, it is essential to complete it by installing a sanitary well cap or seal. This protective barrier not only prevents insects, debris, and surface water from entering the well but also safeguards the water quality. Without a proper well cap, contaminants can easily find their way into the well, compromising the safety of the water supply.

When selecting a well cap, it is important to choose one that is durable and resistant to weathering. UV-resistant materials, such as high-density polyethylene (HDPE), are commonly used to ensure the longevity of the cap. Additionally, the well cap should be properly fitted and securely fastened to prevent any potential tampering or accidental removal.

Water Quality Testing and Treatment

Regular testing of water quality is essential to ensure the water from the well remains safe for consumption. Testing should be conducted periodically for various parameters, including pH levels, mineral content, and the presence of microorganisms or harmful contaminants.

Water quality testing can be performed by certified laboratories or using on-site testing kits. These tests provide valuable information about the overall health of the well and help identify any potential issues that may affect the water quality. For example, high levels of minerals such as iron or manganese can cause discoloration and affect the taste of the water, while the presence of bacteria or viruses can pose serious health risks.

If any issues are detected during water quality testing, appropriate treatment methods should be employed to restore the water’s potability. Filtration systems can be used to remove sediment, bacteria, and other impurities, while disinfection methods such as chlorination or ultraviolet (UV) treatment can effectively kill harmful microorganisms.

In some cases, the water may require additional treatment to address specific concerns. For example, if the water has a high concentration of dissolved minerals, water conditioners or water softeners can be used to reduce hardness and improve taste. It is important to consult with water treatment professionals to determine the most suitable treatment options based on the specific water quality issues.

Regular maintenance and monitoring of the well and its water quality are essential to ensure the ongoing safety and reliability of the water supply. By following proper post-drilling procedures and implementing appropriate treatment measures, the well can continue to provide clean and safe water for years to come.

Maintenance of Water Wells

Regular Check-ups and Cleaning

Regular maintenance of water wells is necessary to prolong their lifespan and maintain their efficiency. It is advisable to schedule annual check-ups with a licensed well driller or technician to evaluate well performance, inspect casings and seals for damages, and conduct any necessary repairs.

In addition to check-ups, periodic cleaning of the well may be required to remove accumulated sediments or biofilms that can affect water flow and quality. Professional well service providers can utilize techniques such as brushing, airlifting, or chemical treatments to address these issues.

Troubleshooting Common Well Problems

Even with proper maintenance, well owners may encounter common problems such as sedimentation, low water pressure, or bacterial contamination. Troubleshooting these issues often requires the expertise of a professional well driller or technician who can identify the root cause and implement appropriate solutions.

By promptly addressing any well problems, well owners can minimize disruptions to their water supply and ensure the continued provision of safe and reliable water.

In conclusion, understanding how water wells are drilled is essential for anyone in need of a reliable, independent water source. From site selection to the drilling process, post-drilling procedures, and ongoing maintenance, there are several factors to consider to ensure the success and longevity of a water well. Regular testing, well development, and addressing common problems are key to maintaining water quality and the overall functionality of the well. By following these guidelines and seeking professional assistance when needed, individuals can enjoy the benefits of a consistent supply of clean water from their water wells for years to come.